Young Fustic Extract

A Guide to Young Fustic Extract

Shepherd Textiles Young Fustic Extract is made from the wood of cotinus coggygria, a sumac species more commonly known as smoketree. Young Fustic grows widely across southern Europe and it was one of the most common yellow dyes of the Medieval era, when it widely employed both by professional dyers and domestic households to give beautiful lemon and gold shades to silks and woolens. However, Young Fustic was largely abandoned by the 1700s when more lightfast yellow dyes became easily available, and it has since fallen into obscurity. Our Young Fustic Extract makes it possible to reproduce the colors of this important but forgotten Medieval dye. It gives intense yellow-orange shades using as little as 5% weight-of-fabric, and is suitable for use on all natural fibers including wool, cotton, and silk.

1. Background on Young Fustic

The dye known as Young Fustic is produced from the wood of the smoketree, cotinus coggygria. The smoketree is a thin-branched and shrubby tree native to southern Europe, Central Asia, and China which belongs to the sumac family. In fact, older texts will identify the species as rhus cotinus (rhus is the genus to which many familiar species of sumac belong, such as Chinese sumac and Staghorn sumac) and the tree was also known historically as Venetian sumac. In botanical terms Young Fustic is entirely distinct from Old Fustic, which is a mulberry tree native to the tropical Americas (although both species will dye similar shades of deep yellow). We have not been able to find any explanation for the etymology of the two names in the historical literature. Why cotinus coggygria should be known as “Young” Fustic, when it was employed as a dye in Europe for many centuries before the import of “Old” Fustic from the Americas, is not entirely clear. Perhaps the name was related to the relative size of the trees and their timber — Old Fustic is a much larger tree and it was imported as immense logs while Young Fustic was apparently found in commerce often in the form of spindly branches (Crace-Calvert 1876:268). In any case the two names had become standard in English dyeing manuals by the 1700s, although occasionally Young Fustic was also referred to as “fustet.”

Because Young Fustic grows widely throughout southern Europe it was a common and inexpensive yellow dye during the Medieval era. Surviving recipes from the 15th and 16th centuries recommend using it alone or in combination with other yellows like weld and broom to dye silks and woolens (see e.g. Monnas 2014:37). However, Young Fustic was always known for having poor fastness to light, so professional dye houses had mostly abandoned it by the end of the Middle Ages when international trade made other yellows more widely available. Victorian experts on dyeing tend to mention Young Fustic in passing as a historical curiosity, but they also tended to agree that “at the present day it has practically fallen into disuse” (Knecht 1910:357). Although Young Fustic was no longer employed by professionals, it seems to have been an important dye in domestic and rural contexts well into the 19th century. Households that did not have access to imported or synthetic dyestuffs could still use Young Fustic to get brilliant (if somewhat fugitive) yellows.

Modern chemical analysis has found that Young Fustic wood contains three primary flavonoid dyes, fisetin, rutin, and myricetin (Wang et al. 2015:3), although fisetin is most likely the flavonoid responsible for the intense orange-yellow shade that is characteristic of Young Fustic. Indeed, Young Fustic Extract gives a beautiful series of yellow-orange shades on fibers mordanted with aluminum. Smaller concentrations of dye (as well as acidic dyebaths) tend to bring out lemon yellow colors. Larger concentrations of dye bring out intense golden yellow or orange-yellow shades. Young Fustic Extract applies well to all fibers including wool, silk and cotton, is very potent, and also has the valuable property of easily dyeing level (even). If it were not for the modest fastness to light it would probably have been one of the most important of the natural yellow dyes, however, Hummel (1885:365) reports that two or three months of direct exposure to sunlight is enough to fade the color entirely. Nonetheless the colors produced by this dye are gorgeous, it is potent and easy to use, and it gives modern dyers the opportunity to experiment with a dyestuff that was historically important but has long been forgotten.

A Forgotten Yellow

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Wear gloves, a mask, and eye protection whenever working with dry pigment powders.

Open carefully to avoid spills or creating dust.

Work in a well-ventilated space. Avoid inhaling the vapors from hot mordant baths and dye baths.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Young Fustic Extract powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

4. Preparation: Pre-Mordant with Alum

Young Fustic Extract requires the use of a mordant for the best results. With alum, it produces shades ranging from lemon yellow to an intense orange-yellow shade. Different fibers require different methods of mordanting with alum to get the best results — see below for details.

For wool: Mordant with 10% WOF alum and 11% WOF cream of tartar.

Weigh out woollen fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to get the amount of alum you will need, and by 0.11 to get the correct amount of cream of tartar.

Scour the wool before mordanting. Fill a dye pot with enough warm water for your fibers to move around freely. Add 1 tsp of pH-neutral soap per pound of wool being scoured (we use Synthrapol). Raise the heat to 180F and maintain for an hour. After an hour, turn off the heat and let the wool cool until it is safe to handle. Transfer to a hot rinsing bath and rinse in one or two changes of water until all soap suds are rinsed out.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of cream of tartar and pour it into the pot. Mix well until dissolved.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

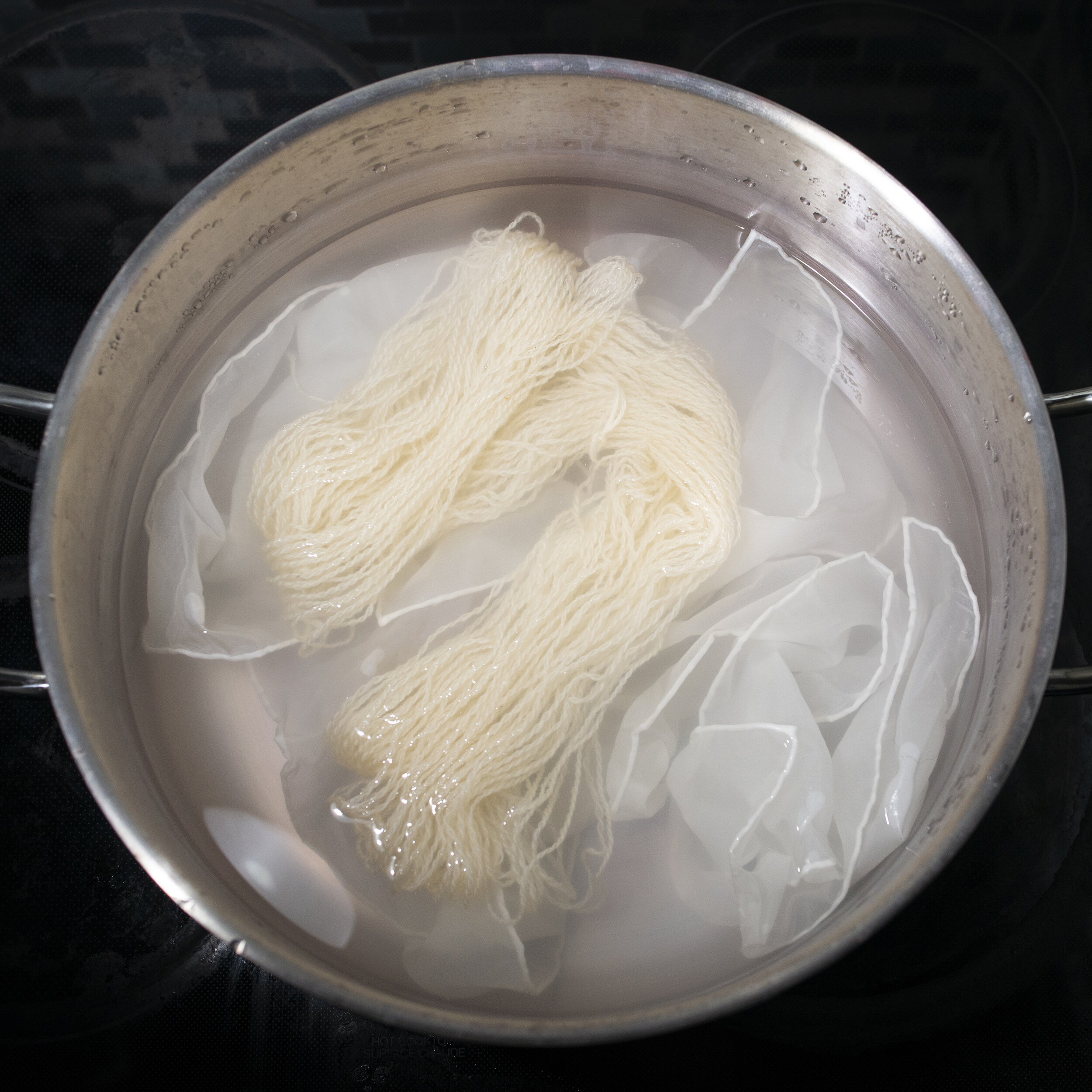

Gently place your woolen fibers into the mordanting solution.

Heat mordant bath to 190F, cover, and maintain the heat for 1 hour. Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye may take better in some places than others.

After an hour, remove from heat and let cool until safe enough to handle.

When ready to rinse, transfer the woolen fibers to a hot rinsing bath (without any soap). Rinse well in one or two changes of hot water to remove excess mordant and cream of tartar.

Dispose of the mordant solution according to local guidelines.

For silk: Mordant at 12% WOF with aluminum lactate.

Weigh out the silk fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of aluminum lactate you will need. OR make a concetrated mordant solution containing 10 grams aluminum lactate per liter of water instead of calculating the quantity based on the weight of the silk (this can give better results when dyeing very thin silks like habotai which barely weigh anything at all)

Scour the silk before mordanting. Fill a dye pot with enough warm water for your fibers to move around freely. Add 1 tsp of pH-neutral soap per pound of silk being scoured (we use Synthrapol). Raise the heat to 160F and maintain for an hour. After an hour, turn off the heat and let the silk cool until it is safe to handle. Transfer to a hot rinsing bath and rinse in one or two changes of water until all soap suds are rinsed out.

Fill a dye pot with just enough hot water for your silk fibers to move around freely.

Weigh out the correct amount of aluminum lactate and add to the dye pot. Mix until fully dissolved [Note: you can use an equal quantity of alum in place of the aluminum lactate, but aluminum lactate will give the best results].

Gently place your fibers into the mordanting solution.

Steep the silk for at least 3 hours in the mordant bath, or preferably overnight. Move the silk around occasionally to make sure that it mordants evenly and no “resists” form (areas like folds, or bubbles trapped under the silk, which can cause the mordant not to penetrate as well).

When ready to proceed, remove the silk and rinse well in lukewarm water.

For best results, do not allow the mordanted silk to dry out all the way before it is dyed; this may result in an uneven or splotchy dye job.

Dispose of the mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Treat with 20% Sumac Extract and then mordant with aluminum lactate.

Scour cellulose fibers well. Traditionally this is done in an alkaline soda ash solution. Add 1 tsp of soda ash and 1 drop of dish soap to a dye pot full of warm water. Add cellulose fibers and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Tan the cotton: fill your dye pot with just enough hot water for the fibers to move around freely and dissolve 20% WOF Sumac Extract into the water. Add your scoured cotton, raise the temperature to 200F, and maintain for one hour. Remove from heat and allow to cool for at least 3 hours. For best results, steep overnight. This process will make the cotton or linen more receptive to mordants. Afterwards, gently wring out the cotton (just enough so it does not drip everywhere) but do not rinse it, as doing so could wash out some of the tannins that are soaked into the fibers.

Hang the tanned cotton up somewhere and let it dry completely. This will help fix the tannins to the fiber before mordanting. However, be careful to hang it up in such a way that there are no folds in it — otherwise you may get an uneven dye job.

Mordant with aluminum lactate: Fill a dye pot with just enough lukewarm water for your fibers to move around freely. Measure out 20% WOF of aluminum lactate, add to the pot, and stir well until dissolved. Place the tanned cotton in the mordant solution and let it steep for at least three hours and preferably overnight, stirring occasionally to make sure the fibers mordant evenly. It is not necessary to heat the mordant solution. When you are ready to begin dyeing, remove the cotton fibers and wring out gently (while wearing rubber gloves).

[Optional] “Chalk” the cotton — fill an empty dye pot or sink with enough lukewarm water for your cotton to move around freely. Add 1 gram chalk (calcium carbonate) per gallon of water and mix well. Add the cotton fibers and let them steep for 20 minutes, stirring them occasionally. This step is optional but recommended, since steeping in a carbonate salt like chalk will help to fix the aluminum to the fibers, as well as to neutralize the acid in the mordant. After 20 minutes, remove and proceed to rinsing.

Rinse the cotton well in lukewarm water. The cotton is now ready to dye.

Dispose of the mordant solution according to local guidelines.

The Recipes

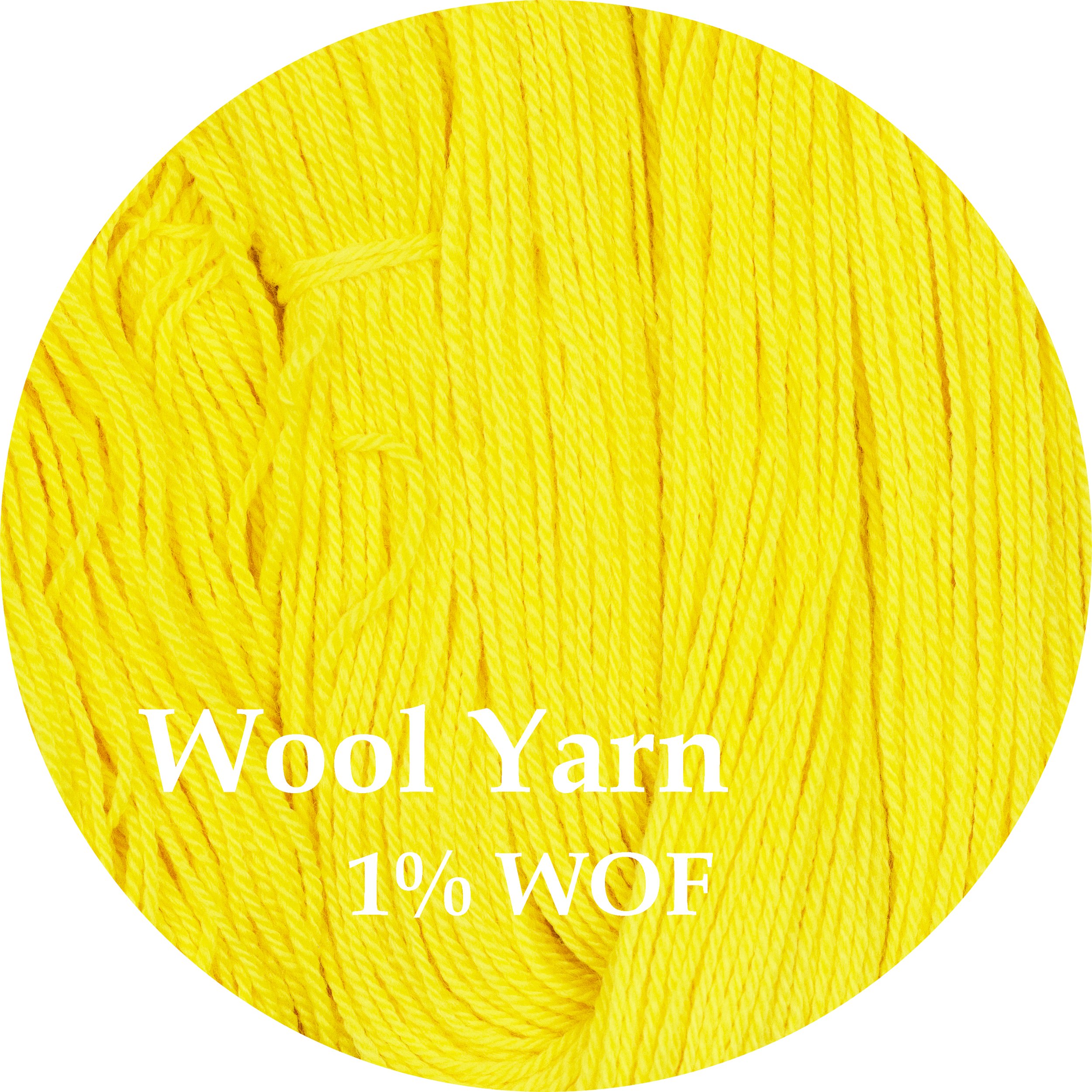

5. Recipe: Yolk Yellow on Woolens

Young Fustic Extract gives excellent lemony yellow shades on wool using as little as 1% weight-of-fabric. The color darkens into a rich egg yolk hue at around 5%. Be sure to stir the wool regularly while the dye bath is heating up so that all the fibers will dye evenly.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of Young Fustic Extract powder. Use 1% for a lemon yellow or 5% for a yolk yellow. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a translucent yellow-orange shade.

Add your wetted, alum-mordanted wool to the dye bath.

Heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly* [see note]. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Young Fustic Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

NOTE: Young Fustic is one of those dyes that starts bonding to fiber very quickly and at a very low heat, beginning somewhere around 130F. As a result, the dye bath needs to be warmed up very gradually and the fibers stirred regularly throughout this time so that everything will dye evenly. Fortunately, Young Fustic has a remarkable tendency to dye level (even), even on piece goods, so as long as the fibers are moved around regularly they should turn out well.

6. Recipe: Olive on Woolens

Like most natural yellow dyes, Young Fustic Extract will shift to an olive or khaki green shade when combined with iron. The particular olive color it yields is on the warmer, yellower end of the spectrum. Although similar results can be achieved by saddening wool with iron after dyeing it, we prefer to pre-mordant wool with iron and dye it olive green directly. Pre-mordanting with iron and plenty of cream of tartar ensures that the iron will not damage the handle (softness) of the wool.

Prepare the wool by mordanting it with iron rather than alum. Follow the directions for mordanting wool in Section 4, but in place of the 10% alum and 11% cream of tartar, use 8% iron (ferrous sulfate) and 12% cream of tartar instead. After mordanting, proceed to the following steps for dyeing.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 5% weight-of-fabric (WOF) of Young Fustic Extract powder. Add to the dye bath and mix well. The dye bath should turn a translucent yellow-orange shade.

Add your wetted, iron-mordanted wool to the dye bath.

Heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the wool dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the wool is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of wool (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Young Fustic Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

7. Recipe: Golden Yellow on Silk

Young Fustic Extract gives fantastic results on silk. It produces a golden-yellow color that is intense and saturated. Note that the quantity of dye required for a dark shade will depend on the weight of the silk being dyed. Thicker weights of silk will need about 5% weight-of-fabric, similar to wool, but very thin silks like satin and habotai will need about 10% weight-of-fabric to develop the same depth of color.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out the appropriate weight-of-fabric (WOF) of Young Fustic Extract powder. Use 5% for heavier weights of silk, or 10% for thin silks like satin and habotai. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a translucent yellow-orange shade.

Add your wetted, alum-mordanted silk to the dye bath.

Heat the dyebath to 180F very gradually, over the course of about 30 minutes, stirring regularly so that the silk dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the silk is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of silk (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Young Fustic Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

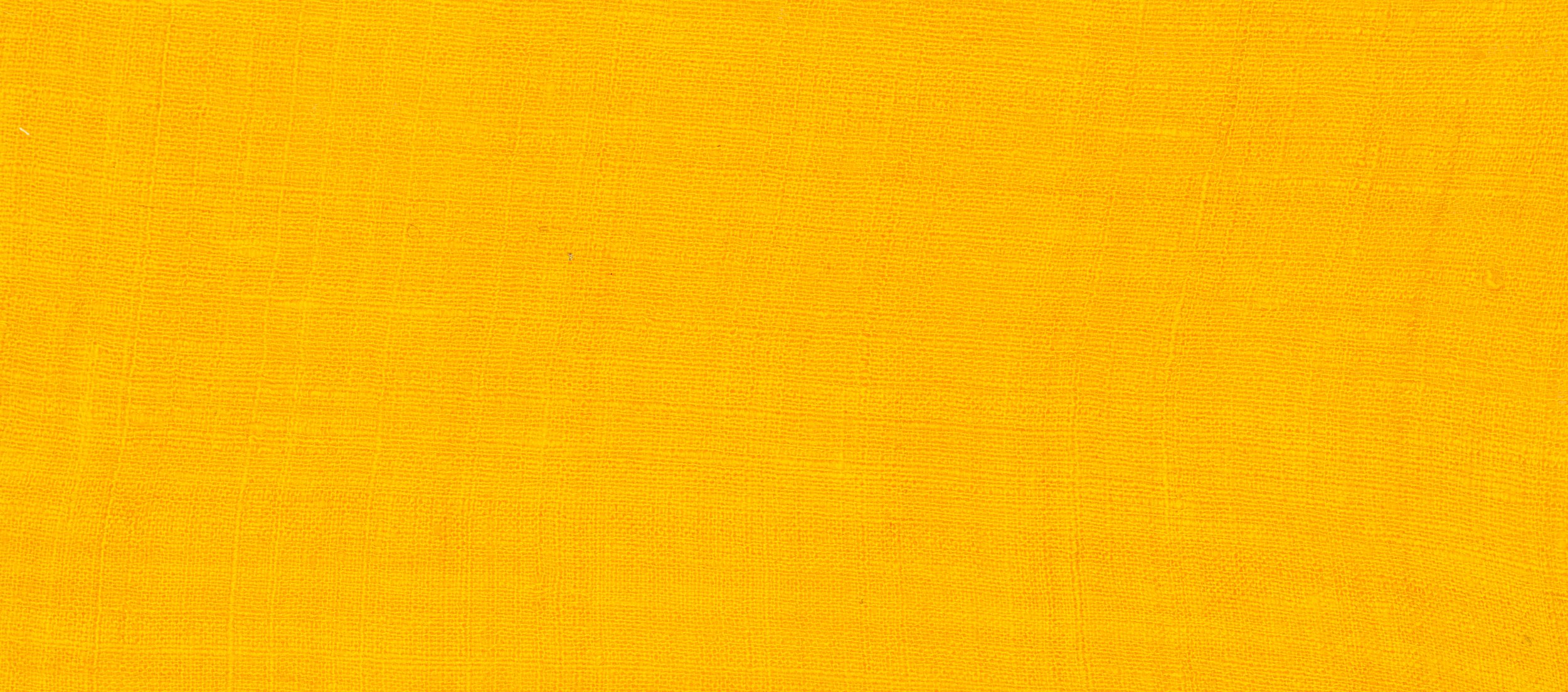

8. Recipe: Golden Yellow on Cotton

Young Fustic Extract also gives great results on cotton, producing a sort of glowing yellow-orange shade.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 5% weight-of-fabric (WOF) of Young Fustic Extract powder. Add to the dye bath and mix well until any clumps are dissolved. The dye bath should turn a translucent yellow-orange shade.

Add your wetted, alum-mordanted cotton to the dye bath.

Heat the dyebath to 200F very gradually, over the course of about 30 minutes, stirring regularly so that the cotton dyes evenly. Maintain this heat for 1 hour and continue to stir occasionally. After 1 hour, turn off the heat and allow to cool.

When the cotton is cool enough to handle safely, remove with tongs and rinse well in warm water with 1 tsp of pH-neutral detergent per pound of cotton (we use Synthrapol). Follow the manufacturer’s directions for best results. Rinse again in a few changes of warm water until all soap suds are rinsed out and the water runs clear. CAUTION: Young Fustic Extract may bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.