Madder Root

A Guide to Madder Root

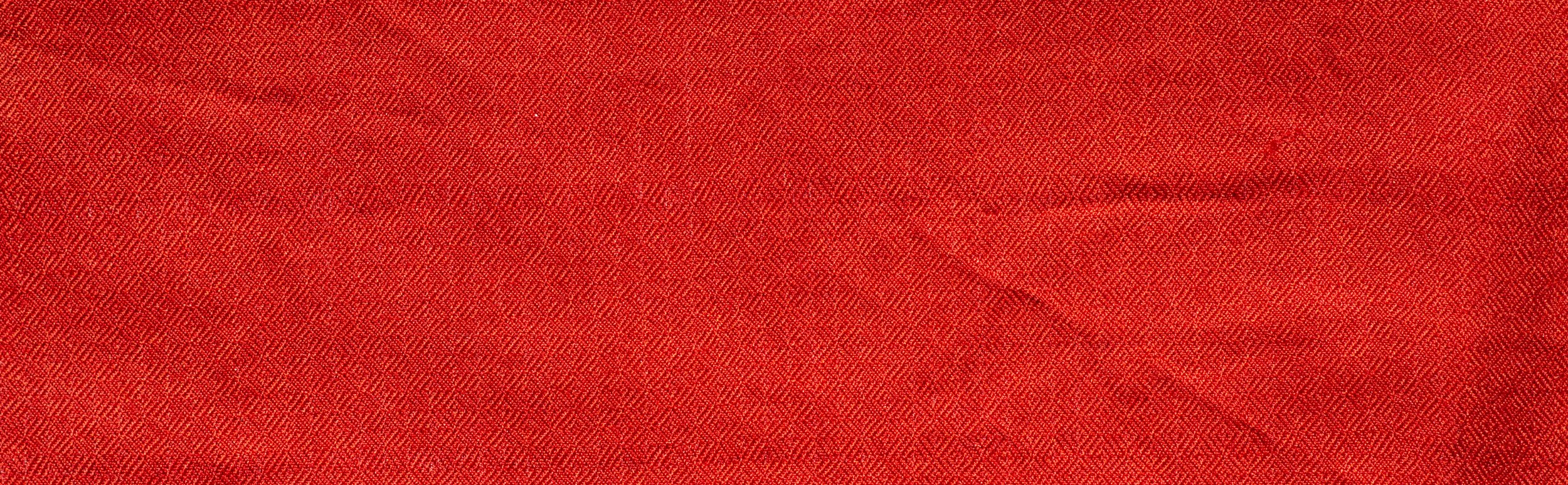

Shepherd Textiles Madder Root Natural Dye contains the ground roots of Rubia tinctorum, the true Turkish madder. Madder was historically the most important of the natural red dyes, because it can produce deeply saturated, lightfast shades of scarlet and crimson. Madder, however, is a remarkably complex root. It also contains yellow, purple, orange, and brown pigments, and dyers in Europe and Asia spent many centuries working out the best ways to extract a clear red. Our madder is an extremely potent grade imported from northern India, with a high proportion of the red dye alizarin. Following the tips below, it will consistently produce a bright, clear scarlet color using 100% weight-of-fabric.

1. Background on Madder Root

“Madder” refers to two species of flowering shrubs in the genus rubiaceae, the same family that includes coffee and gardenias. Rubia tinctorum is known as Dyer’s Madder or Turkish Madder; Rubia cordifolia is commonly known as Indian Madder. Both species produce dozens of anthraquinone compounds in their roots. Several of these are strong natural dyes, and they each produce a different hue. For example, purpurin in the roots produces oranges and yellows, while alizarin produces brilliant, clear reds. This chemical complexity makes raw madder roots extremely challenging to work with, because depending on the temperature, PH, and mordanting process, the orange and brown dyes can easily overpower the red.

Dyers in Anatolia developed a complex process for getting a strong, clear crimson out of madder roots. Fabrics dyed with this “Turkish Red” were highly coveted in Europe, where the secret of getting such a clear red out of madder was not known. European dyers went to extremes to try to recreate it: contemporary recipes suggested steps like pre-mordanting the fiber with dung to “animalize” it, or adding sheep’s blood to the dye bath to increase the depth of the red (see Chenciner 2000:193). Madder fascinated and frustrated dyers for centuries, until the alizarin in the roots was isolated by chemists in France in 1862. In 1871 synthetic alizarin became available, which lead to the end madder’s reign as the classic red plant dye.

Nature’s Strongest Red

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Open carefully to avoid spills or creating dust.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Madder root powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

Pickling lime. Also known as cal (for making corn torillas), a small quantity will increase the depth of reds in the dye bath [Optional].

White vinegar. Assists in extracting the dye from the roots.

4. Preparation: Mordanting with Alum

Madder Root requires a metal mordant to bond effectively to fibers. The classic mordant to use with madder is alum. Indeed, alum plus calcium plus madder was the source of the celebrated shade called Turkish Red. If possible, soak your fibers in water for a few hours before mordanting them, so that the mordant will penetrate deeply and evenly. Likewise, letting the fibers steep in the cooled mordant bath for two or three nights will make the final color richer. Make sure to weigh the fibers first, while they are still dry.

For protein fibers (wool, silk, alpaca, etc.): Mordant at 12% WOF with alum.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.12 to get the amount of alum you will need.

Fill your dye pot with hot tap water, leaving enough room for the fiber.

Weigh out the correct amount of alum and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. If they do not, the dye will take better in some places than others.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results, especially when dyeing thick or tightly woven fabrics. We often let fibers soak in the cold mordant bath for 2 or 3 nights before dyeing with madder to get the deepest, clearest scarlet colors.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers briefly in lukewarm water. The fiber does not need to be thoroughly washed, but any excess mordant should be rinsed out. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For cellulose fibers (cotton, linen, etc.): Scour well and treat with a tannin before mordanting.

Madder Root has a good affinity for cellulose fibers and can give richly saturated reds on cotton. However, the cotton must be well-tanned and then mordanted with alum. The following basic process gives good results.

Scour cellulose fibers well. Traditionally this is done in a highly alkaline soda ash solution. Add 2 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add cellulose fibers and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well. Household detergents like Tide© are also alkaline (PH 11), so you can also toss the fiber in a washing machine on a high-temperature cycle with plenty of detergent. This will not clean them nearly as deeply as simmering with soda ash, but it will yield much better results than not scouring at all.

Apply a tannin to the scoured fabric. Myrobalan is the traditional tannin for madder; use at 30% weight-of-fabric for the the raw ground fruits, or 5% weight-of-fabric for the extract. However, we usually use Sumac Extract at 10% weight-of-fabric, because it is clear and does not alter the hue of the dyed cotton. To use, fill your dye pot with hot water, dissolve the tannin in the dye bath, simmer the fibers for an hour, then allow to cool. For best results, steep overnight. This process will make the cotton or linen more receptive to mordants. After steeping, remove fibers and squeeze dry.

Mordant with alum as described above for protein fibers. Some dyers like to add 1% soda ash to mordant bath to neutralize the PH.

The Recipes

5. Recipe: Turkish Red

The most celebrated shade that Madder Root produces is the intense scarlet called Turkish Red. Getting the most saturated colors requires careful attention to four factors: the strength of the alum mordant, the temperature of the dyebath, the PH of the extraction, and the level of calcium in the water. When all these factors are controlled for, fantastic and deeply saturated reds can result. We recommend using 100% WOF of madder root for a strong scarlet; use half as much for lighter shades of red. If possible, let the fibers steep in an alum mordant bath for at least 24 to 48 hours before using.

Fill your dye pot 3/4 full with warm water.

Adjust the PH to 5 using white vinegar. If you don’t have PH strips handy, add two tablespoons of white vinegar to approximate a slightly acidic dye bath.

Weigh out 100% weight-of-fabric (WOF) of Madder Root powder. Sprinkle over the dye bath and mix well.

Heat the dyebath to 160F for half an hour, stirring occasionally, to extract the color from the roots. The bath should turn a deep, murky red-orange. Remove from heat, cover, and let cool to room temperature. For best results, steep overnight.

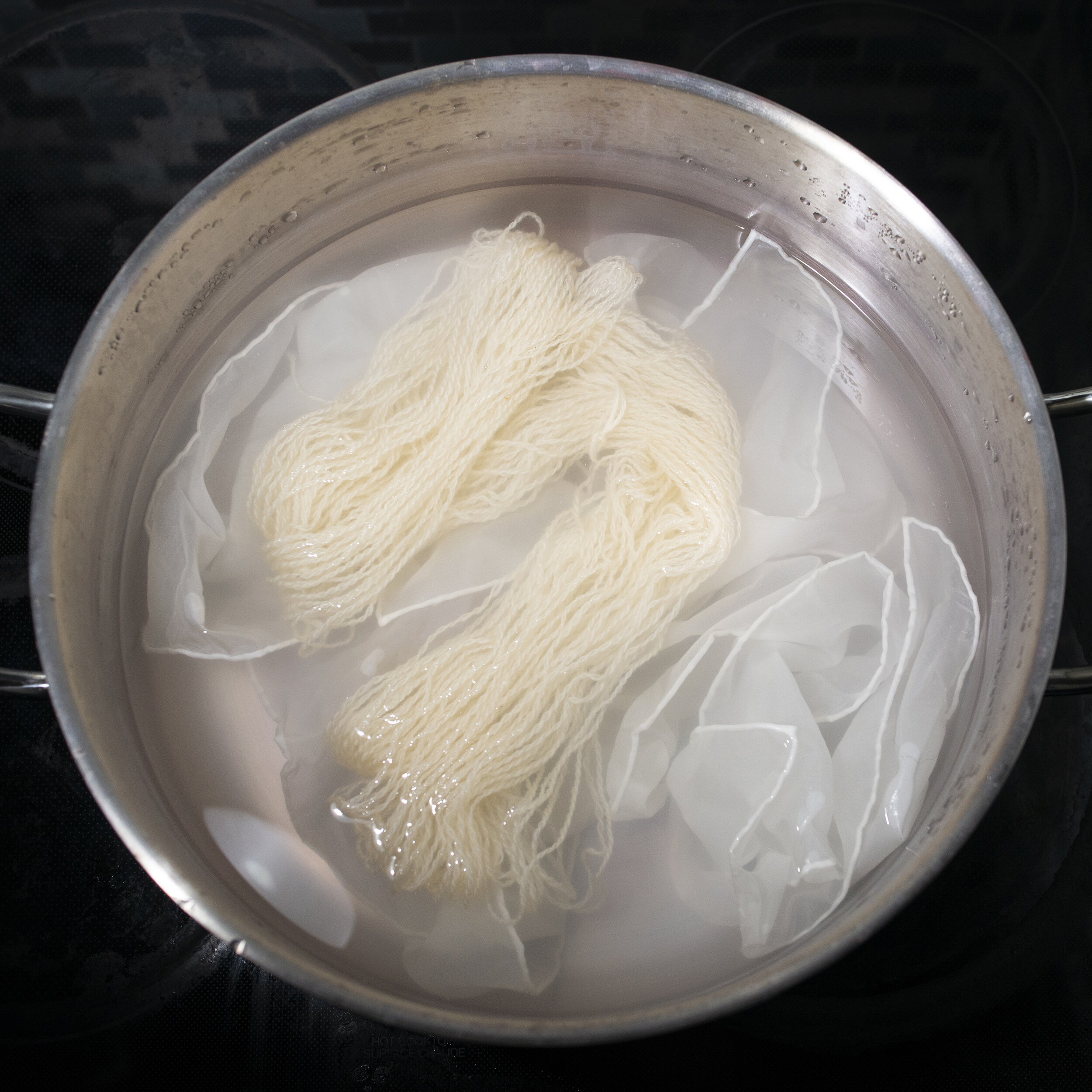

In the morning, filter the dark red extraction bath through cheesecloth or a very fine mesh strainer. Put it in a second dye pot or a holding container, like a clean plastic bucket.

Return the strained roots to the dye pot and wash in a few inches of warm water; this will make sure you get all the dyestuff out of them. Filter this second extraction through cheesecloth or a strainer, adding it to the first extraction of dark red liquid.

Dispose of the strained roots, clean out your dye pot, and pour the dark red extraction liquid back into it. This will be your dye bath.

[Optional]Weigh out 1% weight-of-fabric of calcium hydroxide (a.k.a. pickling lime or cal). Mix in a disposable cup with half a cup warm water. Let it stand for 10 minutes to settle, then pour off the cloudy liquid into the dye bath.

Add your pre-soaked and pre-mordanted fibers to the dye bath.

Heat the dyebath to 140F for wool and silk, or 160F for cotton (higher temperatures may shift the red toward brown). Maintain the heat for 90 minutes, stirring occasionally to make sure all the fibers dye evenly. After 90 minutes, take off the heat and allow to cool to room temperature.

When cool, remove the fibers and rinse briefly in lukewarm water. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Madder Root will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.