Gardenia Blue

A Guide to Gardenia Blue

Shepherd Textiles Gardenia Blue natural dye is made from the seeds of the cape jasmine, gardenia jasminoides. Gardenia seeds have been used for centuries as a yellow dye in East Asia, and in the 1980s Japanese scientists discovered that they would also produce a blue pigment if they were fermented with a natural amino acid. This process was recently improved when scientists identified some naturally heat-resistant amino acids, which made it possible to produce even darker, more concentrated gardenia seed extractions. Use at 10% weight-of-fabric on fibers mordanted with alum. Product of South Korea.

1. Background on Gardenia

Gardenia Blue is produced from the fruit of the cape jasmine, gardenia jasminoides, a flowering shrub native to southern China. The dried fruit has been used as a natural yellow dye for many centuries. In the late 1980s, however, a Japanese scientist discovered that one of the compounds in cape jasmine could be converted to a blue pigment (see Cho et al. 2006:230; Hobbs et al. 2018:696). The process involves reacting genipin in the fruit with one of the basic amino acids, like glycine (found in legumes) or tyrosine (found in cheese). This leads to the formation of a blue pigment often referred to as Gardenia Blue.

There are only a handful of natural blue dye besides indigo, including spirulina (made from algae) and red cabbage extract. Gardenia Blue has major advantages over these alternative natural blues; it it is stable at high and low PH and does not degrade when heated. It is already extremely popular in East Asia, especially in Korea. It is used to color frosting, cakes, ice cream, cosmetics, and blue drinks. However, it remains virtually unknown in the United States. The FDA currently has a working group evaluating Gardenia Blue, but until it receives FDA approval it cannot be used to color foods and cosmetics in the U.S. If and when it does receive approval, it will probably become quite popular.

Shepherd Textiles Gardenia Blue is a new and improved version of this pigment which was developed after a series of technological hurdles were resolved (apparently the main problem with creating this stronger version of the pigment had to do with making it stable at higher extraction temperatures). Like many of the other newer natural dyes (e.g., Mulberry Leaf Extract), Gardenia Blue behaves differently in the dyebath than some of the classic mordant dyes. PH does not affect color but it does effect how well it bonds to fiber: many studies have found that pH 4 is ideal. It also seems to compete rather than bond to certain mordants; pre-mordanting with copper will prevent dye uptake. However, alternate strategies, like post-mordanting and meta-mordanting (mordanting and dyeing in the same bath) can be effective. This is a new dye with few existing guides, and it will reward dyers who enjoy experimenting.

A Rare Natural Blue

2. Safety Precautions

DO NOT INGEST. This product is intended for textile dyeing, not as an herbal supplement.

Avoid eye contact. If eye contact occurs, rinse with cool water.

Not for use as a cosmetic additive; do not apply directly to skin or hair.

Open carefully to avoid spilling or creating dust. Work in a well-ventilated space.

If a spill occurs, quickly wipe up with a paper towel or disposable rag.

Use only dye pots and utensils dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that will be used for food preparation.

Gardenia Blue powder, and all dye baths and mordant liquors made while dyeing, should be kept out of reach of children and pets. Use only with adult supervision.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it has been rinsed.

Candy thermometer. The best way to keep track of temperature is to use a candy thermometer that clips to the side of the dye pot.

Scale. Use a scale to weigh out fiber, mordant, and dyestuff.

Alum mordant. The alum usually used for mordanting is aluminum potassium sulfate, also known as potash alum. It is the same alum that you can find in a jar in the spice section at the grocery store.

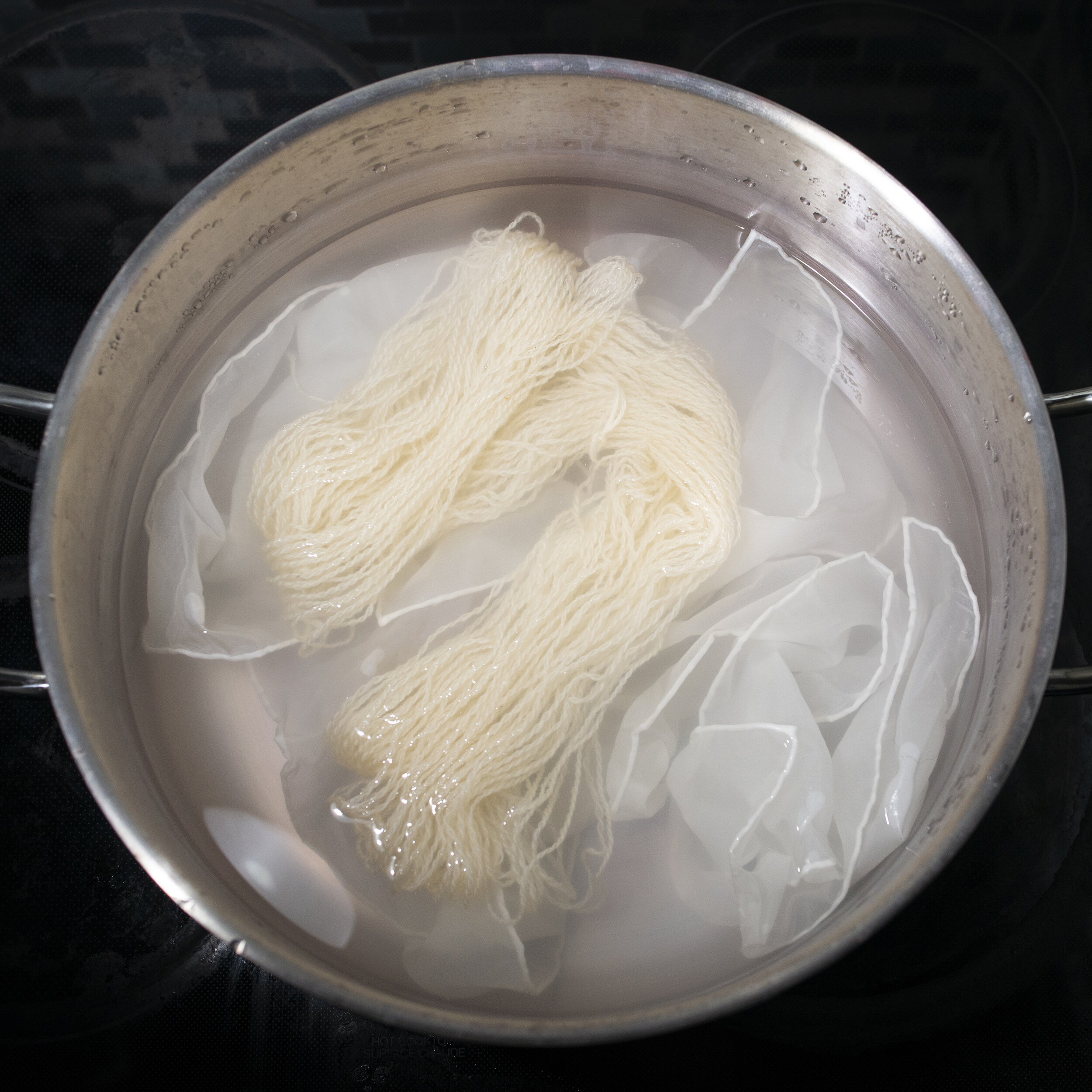

4. Preparation: Mordanting with Alum

Gardenia Blue is substantive on natural fibers; it will dye them without a mordant. However, the color will be noticeably deeper (and probably more lightfast) on wool and silk that are first mordanted with alum. Cotton is the exception - tanning and premordanting in the usual way actually results in a slightly more pale shade of blue. If possible, soak your fibers in water for a few hours before mordanting, so that the mordant will penetrate deeply and evenly. Make sure to weigh the fibers first, while they are still dry.

For wool fibers (wool, alpaca, etc.): Mordant with 10% alum and 11% cream of tartar.

Weigh out the fibers you plan to dye (while they are dry). Multiply that weight by 0.10 to calculate the amount of alum you will need, and 0.11 to calculate the amount of cream of tartar.

Fill your dye pot with enough hot tap water for your fibers to move around freely.

Weigh out the correct amount of cream of tartar and pour it into the dye pot. Mix with a spoon or metal tongs until it has dissolved.

Next, weight out the correct amount of alum and add it to the dye pot. Mix until well dissolved.

Gently place your fibers into the mordanting solution.

Heat mordant bath to 180°F and maintain heat for 1 hour. If you don’t have a candy thermometer, you will have to estimate the temperature. At 180°F, steam vapor will be rising off the water but it will not be bubbling. If your mordant bath starts to bubble, turn down the heat.

Stir every 15 or 20 minutes to make sure fibers mordant evenly. Otherwise, an uneven dye job may result.

After an hour, remove from heat and let cool to room temperature. Once cool, you can immediately proceed to rinsing, or you can leave the fibers to steep overnight in the mordant bath. This can dramatically improve results when dyeing thick yarn or tightly woven fabrics.

When ready to rinse, put on rubber gloves and gently squeeze excess mordant solution back into the pot. Rinse fibers well in lukewarm water. Set aside until ready to dye. Keep out of reach of children and pets.

Dispose of mordant solution according to local guidelines.

For silk: Mordant with 15% alum.

Follow the directions for mordanting wool described above. However, use 15% alum and omit the cream of tartar.

For cellulose fibers (cotton, linen, etc.): Tanning and mordanting is optional.

Gardenia Blue actually produces slightly darker results on cotton that has not been mordanted. However, if you wish to follow the standard tanning and mordanting procedure, the instructions are as follows:

Scour (clean) the cotton by adding 1 tsp of soda ash and 1 drop of dish soap to a 5-gallon dye pot. Add the cotton and heat to 180F-190F for an hour, stirring occasionally. Remove from heat, and when cool enough to handle, rinse and wring out well.

Apply Sumac Extract to the cotton to tan it. Fill your dye pot with just enough hot water for your fibers to move around freely - the more concentrated the tannin bath, the stronger the results will be. Dissolve 20% WOF Sumac Extract into the water. Add the cotton, raise the heat to 180-190F, and maintain for an hour. Remove from heat and allow to slowly cool to room temperature: for best results, steep overnight. After steeping, remove the cotton and gently squeeze out excess liquid (wearing rubber gloves), but do not rinse, as this may rinse out the tannins before they can bond to the mordant. For the very strongest results, hang the cotton up and let it dry before proceeding to mordanting.

Prepare an alum mordant bath using either (a) 20% weight-of-fabric alum + 5% soda ash (washing soda), or (b) 20% weight-of-fabric of aluminum lactate. Either option will create a relatively neutral pH mordant bath that bonds well with cotton.

Heat the mordant bath to 150°F or 160°F, place the cotton in it, and raise the heat to 190°F. Maintain for one hour, stirring occcasionally to make sure the fibers mordant evenly. After one hour, remove from heat. When cool enough to handle safely, remove fibers and rinse well in lukewarm water.

The Recipes

6. Recipe: Ocean Blue

Gardenia Blue produces a beautiful, deeply saturated ocean blue on wool and silk that have been mordanted with alum. However, it is vitally important that the pH of the dye bath be adjusted down to pH 4, which will allow the pigment to bond more easily with the fibers. Gardenia Blue has less affinity for cotton, but it will nonetheless produce a pale sky blue shade.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 10% weight-of-fabric of Gardenia Blue powder. Add to the dyebath and mix well. It will turn a dark blue.

Adjust the pH of the dye bath down to 4 with cream of tartar. About 1 gram of cream of tartar per liter of water should be sufficient, although you may wish to confirm with pH strips.

Add your fibers (premordanted with alum) to the dye bath.

Raise the heat to 180°F for silk, or 190-200°F for wool and cotton. Maintain the heat for 1 hour, stirring occasionally to make sure the fibers dye evenly. After 1 hour, turn off the heat and allow to cool in the dyebath.

Remove the fibers and rinse well in lukewarm water with a few drops of a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Gardenia Blue will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

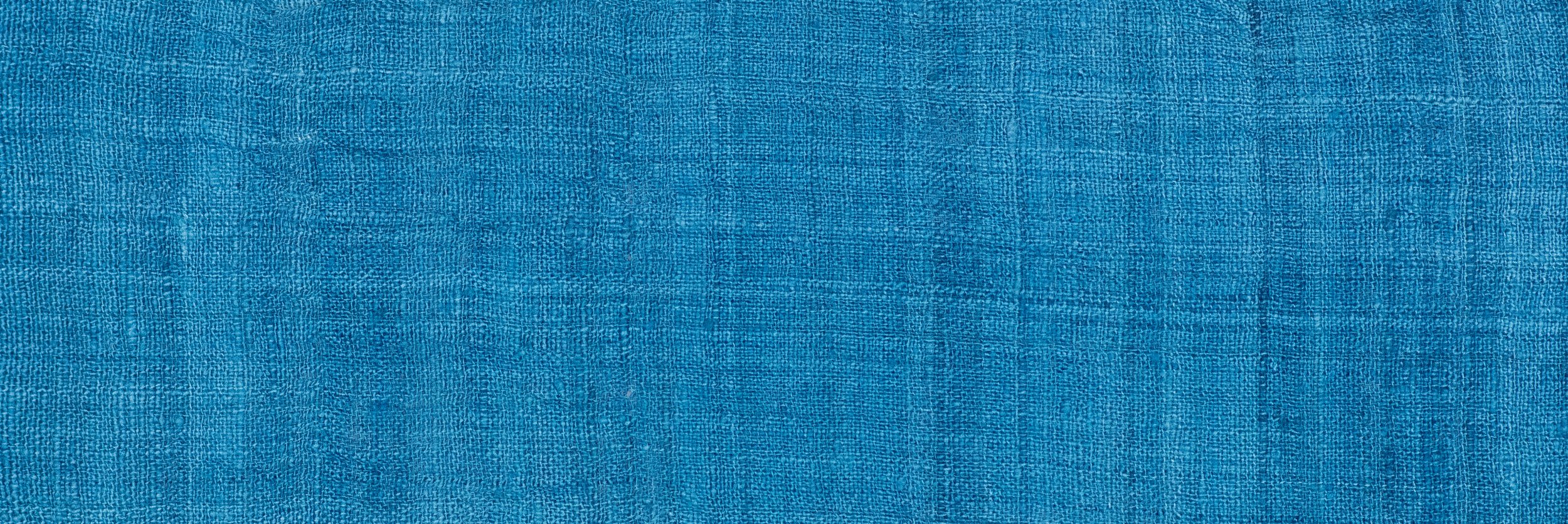

5. Recipe: Turquoise on Wool

Using copper instead of alum will shift the color of Gardenia Blue a bit toward the green end of the blue spectrum. However, premordanting with copper can produce poor results, as it seems to interfere with dye uptake. Darker and more level colors are obtained by saddening - that is, adding the copper mordant directly to the dye bath during the last 20 minutes of dyeing. This method works on wool, but not cotton.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 10% weight-of-fabric of Gardenia Blue powder. Add to the dyebath and mix well. It will turn a dark blue.

Adjust the pH of the dye bath to 4 with cream of tartar. About 1 gram of cream of tartar per liter of water should be sufficient, although you may wish to confirm with pH strips.

Add your cleaned and wetted (but unmordanted) wool to the dye bath.

Heat the dyebath to 190°F and maintain for 40 minutes, stirring occasionally to make sure all the fibers dye evenly.

After 40 minutes, remove the fibers with tongs and set them aside somewhere where dripping dye will not cause any damage; a spare dye pot is ideal.

Weigh out 5% weight-of-fabric of copper mordant (copper sulfate) and add to the dye bath. Mix well for a minute or two to make sure it is completely dissolved.

Return the wool fibers to the dye bath and maintain the heat for another 20 minutes. Afterwards, turn off the heat and allow to cool.

When cool enough to handle safely, rinse the fibers well in lukewarm water with a few drops of a PH-neutral detergent like Synthrapol, which is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Gardenia Blue will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

7. Recipe: Sky Blue on Cotton

Surprisingly, Gardenia Blue actually produces a slightly darker blue shade on cotton that has not been tanned or mordanted ahead of time.

Fill your dye pot with enough warm water for your fibers to move around freely.

Weigh out 10% weight-of-fabric of Gardenia Blue powder. Add to the dyebath and mix well. It will turn a dark blue.

Adjust the pH of the dye bath to 4 with cream of tartar. About 1 gram of cream of tartar per liter of water should be sufficient, although you may wish to confirm with pH strips.

Add your clean but unmordanted cotton to the dye bath.

Heat the dyebath to 190°F-200°F. Maintain the heat for 1 hour, stirring occasionally to make sure the fibers dye evenly. After 1 hour, turn off the heat and allow to cool.

When cool enough to handle safely, remove the fibers and rinse well in lukewarm water. You can either proceed immediately to rinsing with detergent, or hang the fabric up to dry first to help the color set. Make sure to hang it up in the shade somewhere where dripping dye will cause no damage. Direct sunlight may fade the color before it has had time set.

For final rinsing, we recommend using a PH-neutral detergent like Synthrapol, it is designed to wash out loose dye. Follow the manufacturer’s directions for best results. CAUTION: Gardenia Blue will bleed if not thoroughly rinsed out after dyeing.

Hang up to dry out of direct sunlight.

All images and text are copyright of Shepherd Textiles, LLC. Do not reproduce without written permission and attribution.