ALUMINUM ACETATE

The classic mordant for cotton and linen

Aluminum acetate is an aluminum mordant that gives superior results on plant fibers like cotton and linen. It is simple to apply and it can produce intense colors like neon yellow, royal purple, and crimson red. It works well with all natural mordant dyes. Aluminum acetate is an excellent choice for the cotton or linen dyer who is looking to upgrade from standard aluminum sulfate. Note that you will also need chalk (calcium carbonate) to fix the mordant to the fibers. Use at 10% weight-of-fabric (WOF) for basic mordanting. Check out the guide below for detailed recipes and instructions.

1. Background on Aluminum Acetate

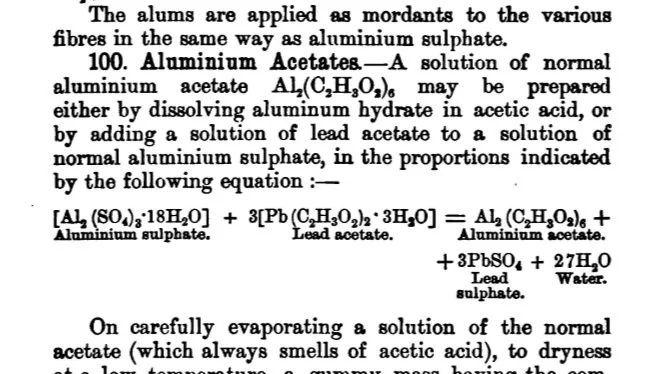

Aluminum acetate is one of several forms of aluminum that are commonly employed for mordanting textile fibers, in addition to aluminum lactate, aluminum formate, and standard aluminum sulfate. Aluminum acetate is the metal salt that forms when aluminum reacts with acetic acid, which is the same acid found in table vinegar. Aluminum acetate behaves quite differently from standard aluminum sulfate when it is dissolved in a mordant bath, and it is a superior mordant for plant fibers like cotton and linen. The reason that normal aluminum sulfate performs poorly on cotton is that when it is dissolved in water, it forms highly sensitive aluminum complexes that tend to hydrolyze (precipitate) before they can actually penetrate the surface of plant fibers. In contrast, aluminum acetate forms very stable aluminum complexes that will penetrate plant fibers fully and evenly. The result on cotton or linen is a thorough mordanting job and bright and beautiful colors after dyeing. Professional dyers have recognized the advantages of aluminum acetate for centuries, and it was the aluminum mordant of choice for many historical cotton dyers and calico-printers.

Aluminum acetate is usually applied to plant fibers through the direct precipitation method. Cotton or linen is soaked in a solution of dissolved aluminum acetate (the strength of the solution will determine how much aluminum is taken up) for long enough for the fibers to absorb the dissolved mordant. The soluble mordant must then be “fixed” or precipitated directly onto the fibers by placing them in a fixing bath. A fixing bath is simply an alkaline bath that contains a carbonate salt like calcium carbonate (chalk), magnesium carbonate, or sodium carbonate. Aluminum acetate precipitates out of solution at high pH, so when the saturated fibers are placed in this fixing bath it forces the dissolved aluminum to precipitate and then it is permanently bonded to the fibers. Aluminum acetate is an excellent choice for cotton dyers and linen dyers who are looking for a mordant that is simple to apply but still gives brilliant and lightfast colors.

2. Safety Precautions

WARNING: Aluminum acetate may cause skin, eye, or respiratory irritation. Harmful if swallowed. Wear gloves, a mask, and eye protection while handling. Do not ingest. Avoid inhaling dust.

FIRST AID: In case of skin or eye contact, rinse with water for a few minutes. If discomfort persists, seek medical advice. If swallowed, seek immediate medical attention.

For textile projects only.

Open carefully to avoid spills. If a spill occurs, quickly wipe up with a paper towel or rag.

Use this product only with pots and utensils that are dedicated to dyeing. Do not use any pots, containers, spoons, tongs, thermometers, or other utensils that are also used for food preparation.

Store out of reach of children. To prevent accidental ingestion, all dye baths and mordant baths made while dyeing should also be stored out of reach of children and pets. Use only with adult supervision.

SDS available on request.

Shepherd Textiles, LLC is not liable for any misuse of this product or any unintended staining of your clothing, workspace, or other property. Use only as directed.

3. Recommended Supplies

Dye pot or plastic bucket. Use a dye pot large enough to hold all your fibers, with plenty of room for them to move around and for the liquid to circulate freely. A stainless steel stock pot usually works well. Since aluminum acetate does not need to be applied at a boiling heat, a heavy-duty plastic bucket can be used instead.

Metal tongs. A pair of tongs is useful for stirring and taking fabric out. Use tongs dedicated to dyeing, and not for food preparation.

Rubber gloves. Wear rubber gloves while handling mordanted/dyed fiber before it is rinsed.

Calcium carbonate (chalk). Chalk is used to permanently fix the mordant to the fibers.

Candy thermometer. A cheap candy thermometer that clips to the side of the dye pot will make it easier to track the temperature.

Scale. Use a scale to weigh out the mordant and the chalk.

Tannin [optional]. For the darkest colors, Aluminum Acetate should be applied to cotton or linen that has been treated with a tannin like Sumac Extract or Oak Gall Light.

Recipes

4. The Direct WOF Mordanting Method

This is the method for mordanting with aluminum acetate that is commonly described in modern natural dyeing manuals. It is a quick and simple version of the direct precipitation method, using a weight-of-fabric (WOF) calculation for the quantity of mordant, and chalk as the fixing agent. The advantage of using aluminum acetate in this way is that it does not require any tannin pretreatment, the mordant bath only requires a gentle heat, and only a modest amount of mordant is used. This method produces fine bright colors, but it works best for light or medium shades. For darker colors, especially on thin fabrics like cotton tshirts or fine linen scarves, a higher concentration of aluminum acetate must be used (see Section 5).

Cotton shirt + 4% French Weld Exract

Cotton shirt + 40% Madder Root

Cotton shirt + 2% Royal Logwood Extract

Scour the cotton or linen fibers well.

Fill a dye pot or plastic bucket with enough water for fibers to move around freely [see NOTE 1]. The water should be heated to 130°F (54°C). Lower temperatures will slow down the absorption of the mordant by the cotton fibers, while significantly higher temperatures can risk precipitating the aluminum before it has had a chance to be absorbed, especially if the water is hard.

Weigh out 10% weight-of-fabric (WOF) of Aluminum Acetate. Add to the water and mix well until dissolved.

Gently add your scoured cotton or linen fibers. Using tongs or a similar utensil, work the fibers in the mordant bath to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath.

Cover the pot or bucket and let the fibers steep for 2 hours. Stir the fibers two or three times while they are steeping to make sure they mordant evenly.

After 2 hours, the fibers are ready to “fix” [see Note 2]. Fill a second dye pot or plastic bucket with enough hot tap water (110°F-120°F) for your fibers to move around freely. Measure out 10 grams of chalk (calcium carbonate) per liter of water in this fixing bath. Add the chalk and mix well until dispersed. The fixing bath should be a thick, milky white color.

Wearing gloves, remove the cotton fibers from the mordant bath. Gently squeeze some of the excess mordant liquid out of the fibers and back into the mordant bath. Then, place the fibers into the chalk fixing bath. Work the fibers briefly to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath, and then leave them to steep for 1 hour.

After 1 hour, remove the cotton from the chalk fixing bath and rinse well in several changes of hot water (without using any soap or detergent). There will be a lot of chalk soaked into the fibers so it will take a bit of rinsing to get it all out.

Proceed directly to dyeing. The swatches above show cottons tshirts mordanted using this method, and then dyed with either 4% French Weld Extract (yellow), 40% Madder Root (red), or 2% Royal Logwood Extract (purple).

NOTE 1. The water used for the mordanting step should be soft or distilled. Extremely hard water can interfere with the mordanting because the aluminum can bond to the calcium in the water and precipitate prematurely. Most municipal tap water should work fine, but if you know you have extremely hard water, you might need to use an alternate water source for best results.

NOTE 2. Aluminum acetate needs to be “fixed” in order to precipitate the soluble mordant onto the fibers (otherwise much of it will just wash out during the dyeing process). The precipitation of aluminum acetate is accelerated by high pH and heat. Placing the saturated fibers in a warm, alkaline “fixing bath” will cause the dissolved aluminum acetate to precipitate, and the mordant that is soaked into the cotton fibers will permanently bond to them. In theory, a variety of alkaline salts will work as the fixing agent — in the past, “silicate of soda” was favored by professional dyers — but calcium carbonate (chalk) is mostly used today because it is safe and non-toxic.

5. The Direct GPL Mordanting Method

A stronger concentration of aluminum acetate is required to get darker colors on cotton and linen. Instead of calculating the amount of aluminum acetate to use based on the weight of the fibers, this method uses a concentrated solution of aluminum acetate at 15 grams per liter (GPL). The main drawback of this method is that building the initial mordant bath is more expensive. To mordant a tshirt, for example, at least 4 or 5 liters of water should probably be used so that the tshirt has enough room to move around freely. That means at least 60 or 75 grams of aluminum acetate will have to go into the initial mordant bath. However, this concentrated mordant bath can be topped off and re-used repeatedly for mordanting subsequent pieces, so it becomes more cost-effective if you have a lot of cotton to dye.

Cotton shirt + 5% French Weld Extract

Cotton shirt + 80% Madder Root

Cotton shirt + 3% Royal Logwood Extract

Scour the cotton or linen fibers well.

Fill a dye pot or plastic bucket with enough water for fibers to move around freely [see NOTE 1]. The water should be heated to 130°F (54°C). Lower temperatures will slow down the absorption of the mordant by the cotton fibers, while significantly higher temperatures can risk precipitating the aluminum before it has had a chance to be absorbed, especially if the water is hard. Make a note of how much water goes into the pot or bucket.

Weigh out 15 grams of Aluminum Acetate for each liter of water in the mordant bath. Add and mix well until fully dissolved [see NOTE 2].

Gently add your scoured cotton or linen fibers. Using tongs or a similar utensil, work the fibers in the mordant bath to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath.

Cover the pot or bucket and let the fibers steep for 2 hours. Stir the fibers two or three times while they are steeping to make sure they mordant evenly.

After 2 hours, the fibers are ready to “fix.” Fill a second dye pot or plastic bucket with enough hot tap water (110°F-120°F) for your fibers to move around freely. Measure out 10 grams of chalk (calcium carbonate) per liter of water in this fixing bath. Add the chalk and mix well until dispersed. The fixing bath should be a thick, milky white color.

Wearing gloves, remove the cotton fibers from the mordant bath. Gently squeeze some of the excess mordant liquid out of the fibers and back into the mordant bath. Then, place the fibers into the chalk fixing bath. Work the fibers briefly to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath, and then leave them to steep for 1 hour. Stir once or twice to make sure they fix evenly.

After 1 hour, remove the cotton from the chalk fixing bath and rinse well in several changes of hot water (without using any soap or detergent). There will be a lot of chalk soaked into the fibers so it will take a bit of rinsing to get it all out.

Proceed directly to dyeing. The swatches above show cottons tshirts mordanted using this method, and then dyed with either 5% French Weld Extract (yellow), 80% Madder Root (red), or 3% Royal Logwood Extract (purple).

The mordant bath can be saved and reused for mordanting subsequent batches of cotton. It can be topped off by adding more aluminum acetate to replenish what has been used up. There is no way to calculate exactly how much mordant any particular piece of cotton will absorb, but a good place to start is to assume that each piece of mordanted cotton will absorb 10% of its weight in aluminum acetate, so an equivalent amount should be added back into the mordant bath to replenish it. Eventually the aluminum in the mordant bath will precipitate as aluminum hydroxide — when the bath becomes very cloudy or full of flakes, it is time for it to be discarded.

NOTE 1. The water used for the mordanting step should be soft or distilled. Extremely hard water can interfere with the mordanting because the aluminum can bond to the calcium in the water and precipitate prematurely. Most municipal tap water should work fine, but if you know you have extremely hard water, you might need to use an alternate water source for best results.

NOTE 2. The amount of mordant that plant fibers like cotton will absorb is determined by the concentration of the mordant bath solution. If the solution is dilute (say, 10 grams of Aluminum Acetate dissolved in 12 liters of water), the cotton will not absorb nearly as much mordant as if the solution is concentrated (say, 15 grams of Aluminum Acetate per liter, as described here). That is why calculating the amount of mordant in terms of Grams Per Liter will yield darker colors than calculating the amount of mordant by Weight of Fabric, especially when we are mordanting thinner and lighter fabrics like tshirts. This is in contrast to wool, which strongly attracts mordant ions and will absorb the mordant out of solution regardless of whether the mordant bath is dilute or concentrated.

5. The Tannin Mordanting Method

Another way to get dark colors on cotton or linen is to treat them with a tannin before being mordanting them with aluminum acetate. The tannins saturated into the fibers will react with the aluminum in the mordant bath to form insoluble aluminum-tannate complexes, which fix themselves permanently to the fiber. This is a different approach to mordanting than the direct precipitation method. It produces excellent results and very dark colors, and less mordant is required than when using the Direct GPL Method. Note that aluminum acetate will not complex with tannins at room temperature (unlike, say, ferrous sulfate) so the mordant bath still needs to be heated to between 130°F and 140°F for good results.

Cotton shirt + 6% French Weld Extract

Cotton shirt + 100% Madder Root

Cotton shirt + 4% Royal Logwood Extract

Scour the cotton or linen fibers well. Prepare them by treating them with a tannin like Sumac Extract, Oak Gall Extract, or Oak Gall Light. In general, the procedure is to dissolve 10-12% of the tannin into a dye pot with enough water for the fibers to move around freely, add the cotton or linen, bring to a boil, then remove from the heat, cover, and let steep for at least 3 hours or overnight. Afterwards the fibers should be gently wrung out, but not rinsed.

Fill a dye pot or plastic bucket with enough water for fibers to move around freely. The water should be heated to between 130°F (54°C) and 140°F (60°C). Aluminum Acetate will not complex efficiently with tannins at lower temperatures, while significantly higher temperatures risk precipitating the aluminum before it fixes to the tannins. Note that we can push the temperature just a bit higher than when using the direct precipitation method.

Weigh out 12% weight-of-fabric (WOF) of Aluminum Acetate. Add to the mordant bath and mix well until fully dissolved [see Note 1].

Gently add your tannin-treated cotton or linen fibers. Using tongs or a similar utensil, work the fibers in the mordant bath to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath.

Cover the pot or bucket and let the fibers steep for 2 hours. Stir the fibers two or three times while they are steeping to make sure they mordant evenly.

After 2 hours, the fibers are ready to “fix” [see Note 2]. Fill a second dye pot or plastic bucket with enough hot tap water (110°F-120°F) for your fibers to move around freely. Measure out 10 grams of chalk (calcium carbonate) per liter of water in this fixing bath. Add the chalk and mix well until dispersed. The fixing bath should be a thick, milky white color.

Wearing gloves, remove the cotton fibers from the mordant bath. Gently squeeze some of the excess mordant liquid out of the fibers and back into the mordant bath. Then, place the fibers into the chalk fixing bath. Work the fibers briefly to make sure they are evenly saturated. Make sure they are completely submerged and no bubbles are trapped underneath, and then leave them to steep for 1 hour. Stir once or twice to make sure they fix evenly.

After 1 hour, remove the cotton from the chalk fixing bath and rinse well in several changes of hot water (without using any soap or detergent). There will be a lot of chalk soaked into the fibers so it will take a bit of rinsing to get it all out.

Proceed directly to dyeing. The swatches above show cottons tshirts mordanted using this method, and then dyed with either 6% French Weld Extract (yellow), 100% Madder Root (red), or 4% Royal Logwood Extract (purple).

NOTE 1. When mordanting fibers that have been pre-treated with a tannin, we can use weight-of-fabric (WOF) to calculate the amount of aluminum acetate needed, rather than making a concentrated solution based on grams per liter (GPL). In general, the amount of mordant that cotton or linen will absorb out of solution is a function of how concentrated the solution is, in grams per liter, which is why the Direct GPL Method gives good results. When cotton or linen is treated with a tannin, however, it behaves more like wool in that it will absorb the mordant out of the mordant bath regardless of whether the solution is dilute or concentrated (for practical purposes, anyways).

NOTE 2. In theory, chalking is not necessary when Aluminum Acetate is applied to fibers that have been saturated with a tannin, because the formation of an aluminum-tannate complex is what fixes the mordant to the fiber. In practice, however, the best results are still obtained by chalking after mordanting, so this step should not be skipped. Very likely there will be extra aluminum soaked into the fibers that will be “fixed” during the chalking bath.

*All text and images are copyright of Shepherd Textiles, LLC. Do not reproduce without permission and attribution.